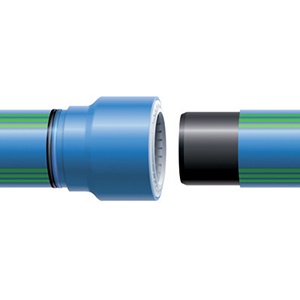

Spigot and socket systems are well established in water supply applications for decades because of its ease of assembly. It represents a practical alternative to welding and offers a number of benefits, especially for small sections of pipelines.

Short installation and processing times through simple and fast assembly and short preparation times, installation irrespective of weather, as well as processing without any specialty equipment – and all this while maintaining the familiar flexibility, permanent tightness and pressure resistance. Also an ideal solution for smaller installers that don´t have easy access to welding technicians.

The new axially force locked egeplast spigot and socket system now satisfies the demand of water utilities to combine the conventional spigot and socket joint with the numerous advantages of PE pipes.

• Proven flexibility

• Axially force locking, no need for thrust blocks

• Permanent leak-tightness

• Internal lip seal enables nominal pressures up to 16 bar

• Installation irrespective of weather

• Simple and fast installation, high daily output

• Time-saving (no welding, no cooling and no idle times)

• No welder training needed

• Processing without the need for specialty equipment

• No problem with residual water

• Safe transition to other pipe materials such as cast iron, vitrified clay, PVC etc.

• Also ideal for repairs and subsequent integration

• Pressure can be applied immediately after installation

• Pre-assembled in the factory, industrially manufactured quality

• As an option: Protection of the pressurebearing pipe through additional protective layer

• Fitting accuracy due to adapted socket/pipe tolerances

• No embedding in sand needed when using high quality RC materials

• Complete system – comprehensive range of fabricated fittings and wide range of possibilities (Tees, bends, elbows, reducers, four-way connectors, duck foot bends, couplers etc.)

• Simple procurement, no additional storage of adapters